Trình điều khiển servo nhập khẩu 3 trục giúp máy hoạt động nhanh hơn, ổn định hơn và chính xác hơn

Việc cấp dữ liệu luân phiên đảm bảo máy làm việc chính xác và tiết kiệm nguyên liệu hơn.

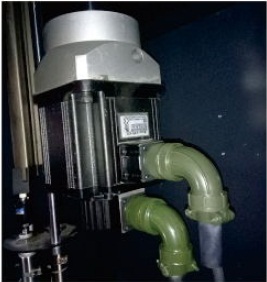

Động cơ servo 1500W đảm bảo lực uốn và ổn định hơn

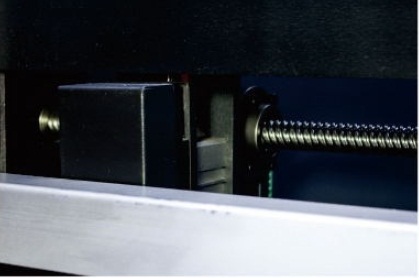

W30 sử dụng công cụ tiện CNC có độ bền cao và độ hao hụt thấp, mỗi dao có 8 góc, không cần mài dao chỉ thay đổi góc, quá trình ít tiếng ồn và không có bụi. Bằng cách áp dụng thiết kế kẹp và nạp tiến bộ, lãng phí vật liệu sẽ được tránh một cách hiệu quả và chi phí được tiết kiệm về cơ bản. Thông qua vật liệu cố định, vít me bi chất lượng cao và dẫn hướng tuyến tính, sự kết hợp hoàn hảo giữa bộ truyền động servo công suất cao, hệ thống cân bằng trước của vật liệu bù giúp loại bỏ hiện tượng đầu máy toa xe truyền thống dễ bị trượt trong quá trình cấp liệu, và tránh sự biến dạng của tấm trong quá trình uốn.

| Slotting Method | Alloy milling cutter slotting |

| Bending Method | Double blade alternate bending system |

| Package Size | 1880*780*1850mm |

| Suitable Material | Double ball-screw progressive mode |

| Suitable Material | Aluminum plate, Stainless steel, Galvanized plate |

| Material Height | 20~300mm |

| Material Thickness | 0.4~1.8mm |

| Min.BendingAngle | R15 |

| Control System | 4 axis control system (3axis servo control) |

| File Format | Dxf.Plt.Ai |

| Power | AC220V, 50Hz, 4.0Kw |

| Machine Weight | 750Kg |

>>> Xem thêm sản phẩm liên quan: Máy bẻ chữ inox và nhôm W10

0932141612

0932141612